Research Introduction (for 3rd-year students)

The Yanagitani laboratory is doing research on ultrasonic wave generation devices and medical engineering applications. Our lab aims at practical research and manufacturing.

- What is ultrasonic wave?

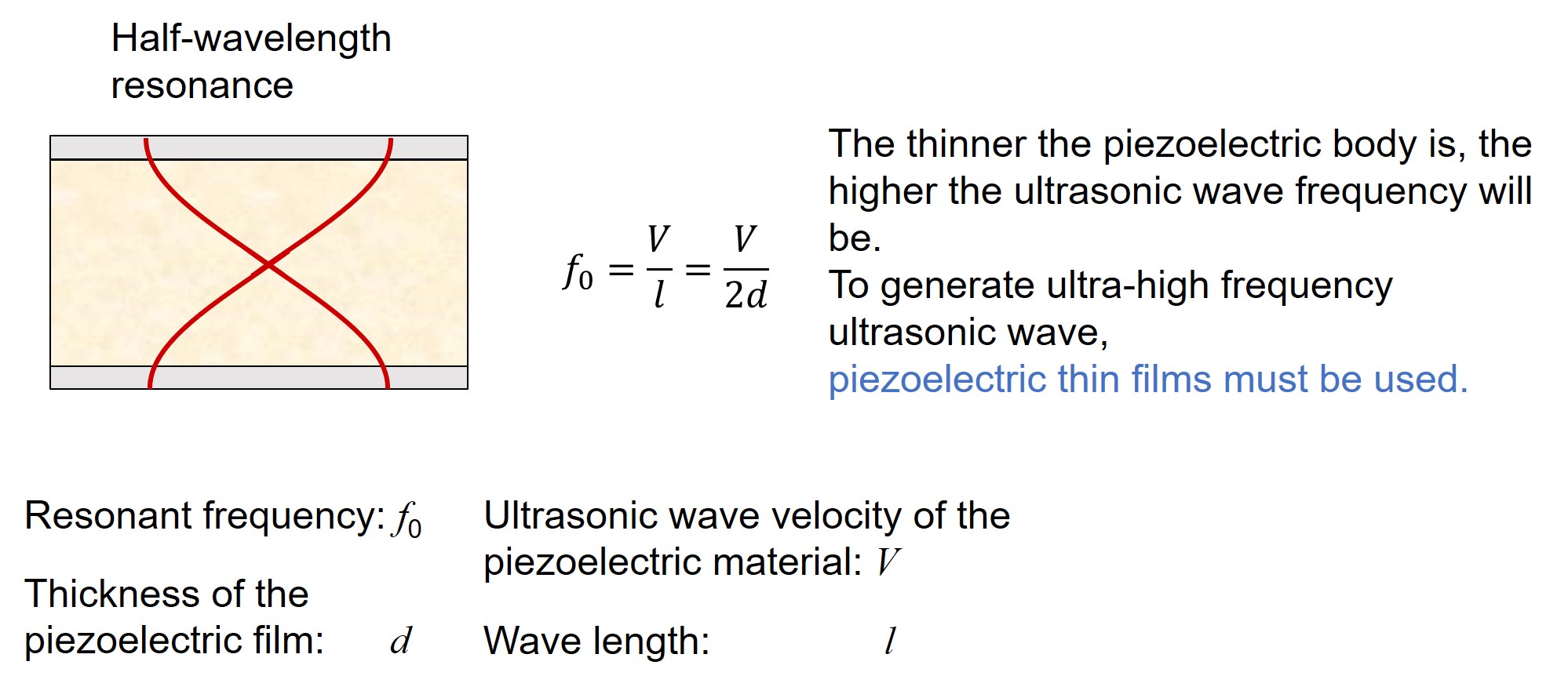

- Ultrasonic wave is defined as “inaudible sound with high frequency for human” the frequency of which generally exceeds 20 kHz.

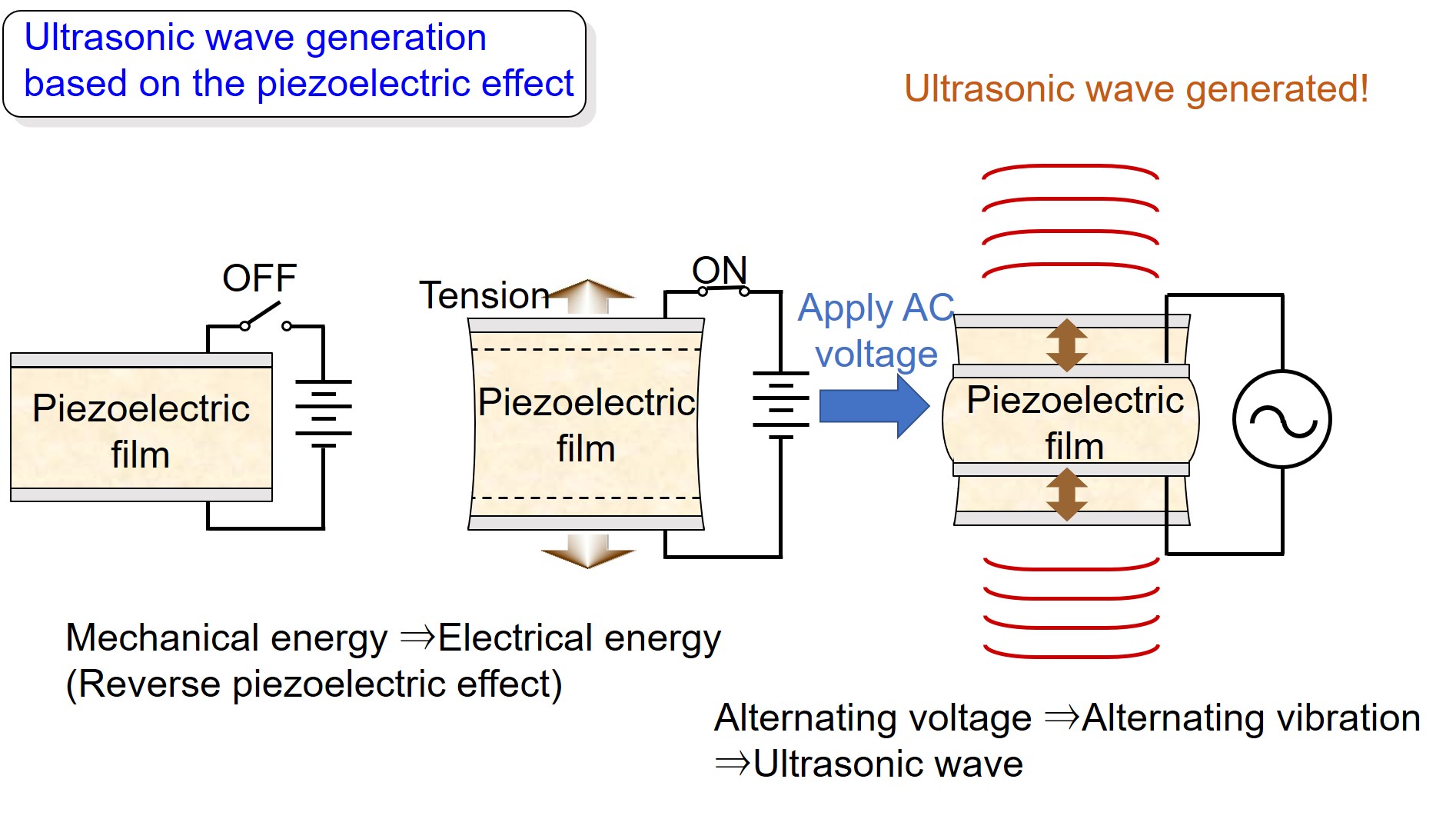

Piezoelectric materials vibrate strongly at their natural frequencies

Applied research on piezoelectric thin films

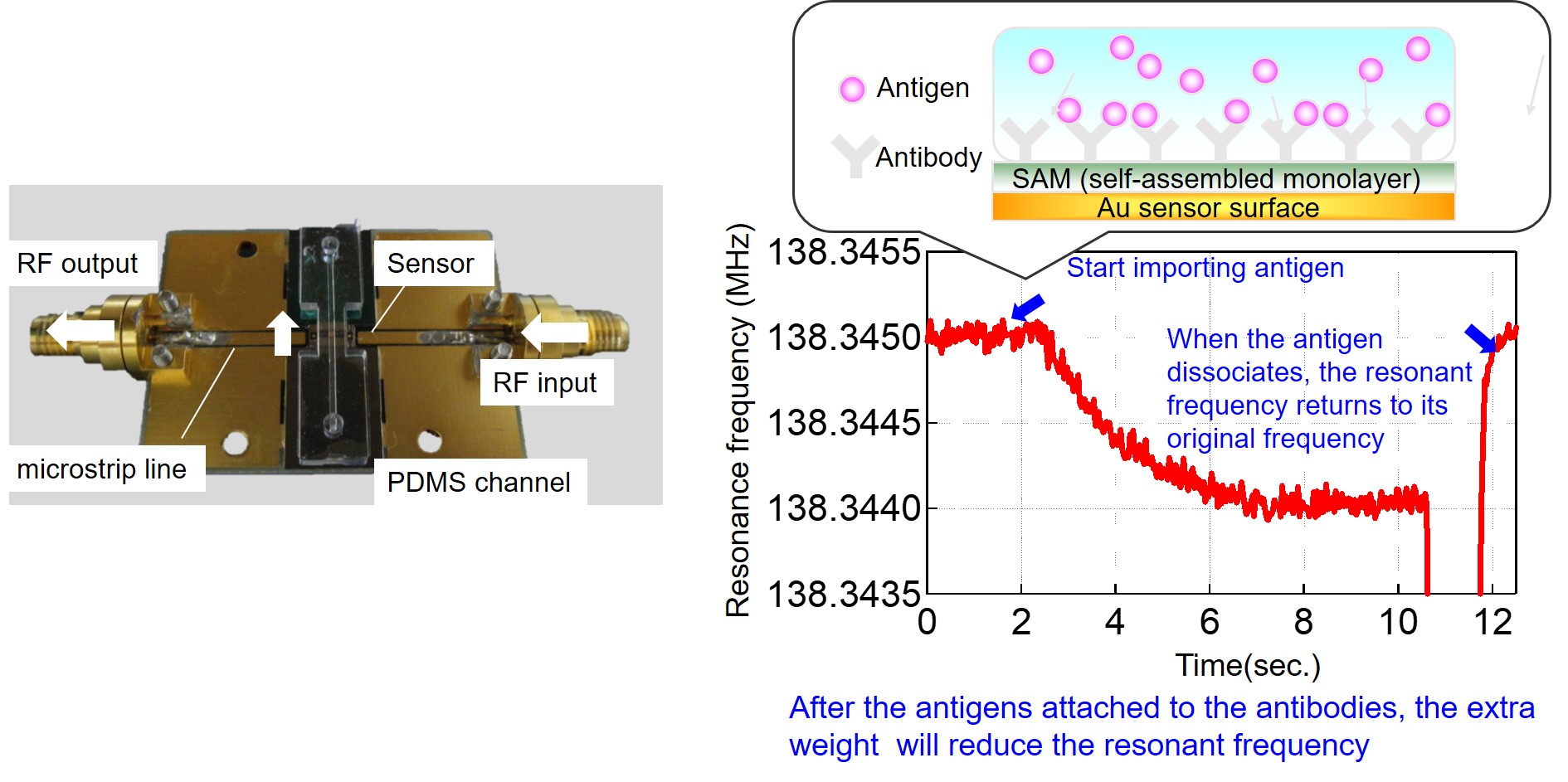

1. Antigen-antibody reaction sensor

In developed countries, the increase of medical care costs has become a social problem. In order to reduce expenditure, the development of disease prevention medicine is very important. In this study, we are doing research on the sensors that detect lesion marker (cancer marker) proteins from the changes of the ultrasonic wave vibration.

When a car passes a bridge, which vibrates at a specific frequency, the extra weight will cause the variation of vibration frequency. In the same way, if the antigens are attached to the nano-sized bridge with the antigen-coated surface, which is also called the antigen-antibody reaction, the vibration frequency will be changed due to the reaction, and the antigen concentration can be inferred from the variation.

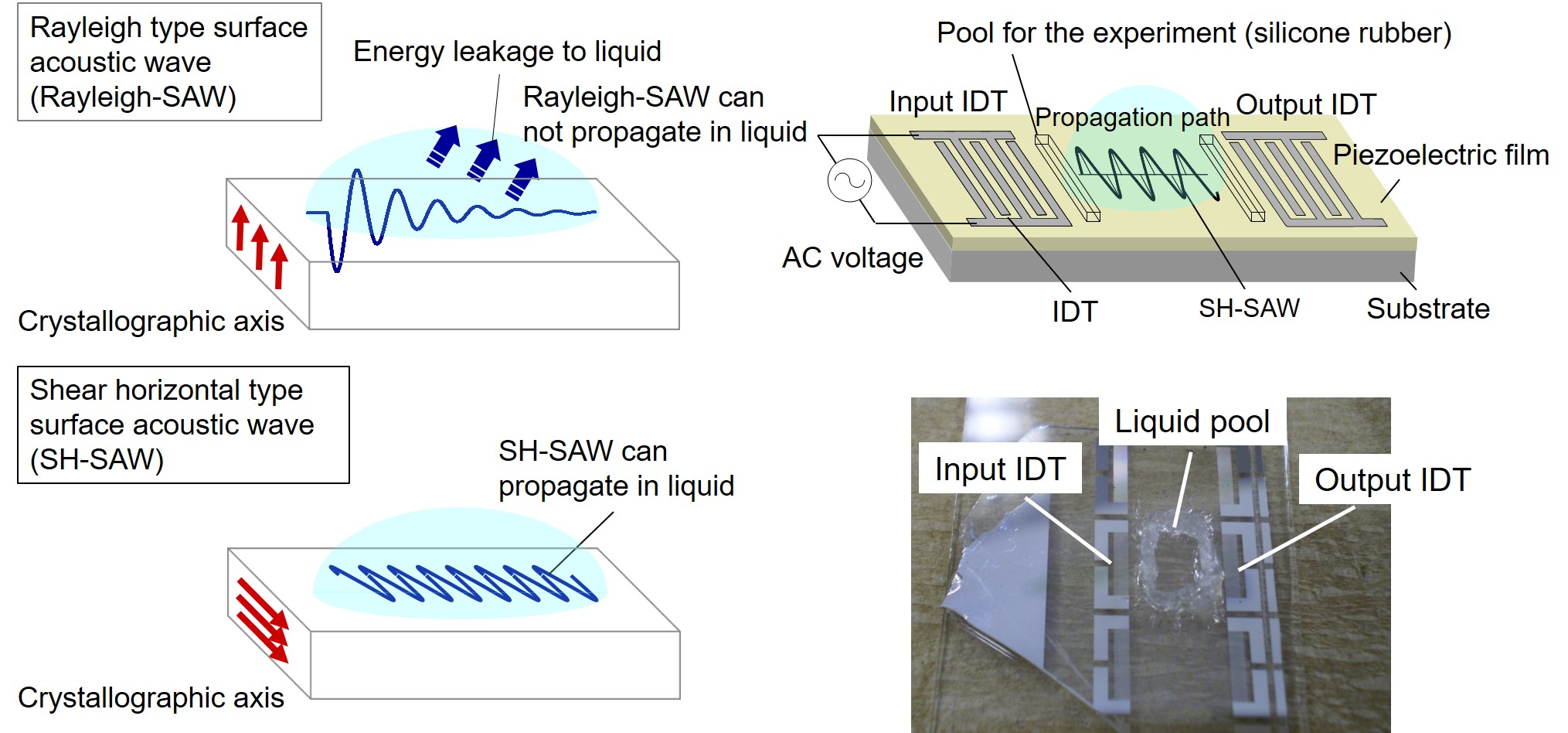

Because normal piezoelectric thin films vibrate in longitudinal mode, they can not be used for biological detection. If the liquid such as the biological sample is attached to the thin film, the energy of vibration will leak into the liquid and make it impossible for the film to vibrate.

Our lab has fabricated the world’s first piezoelectric film that excites pure shear waves without any longitudinal waves [1,2]. This makes the film able to maintain vibration even in liquid. Our team has successfully detected the antigen with high sensitivity; we are able to detect the equivalent of a bowl of antigen in a 25-meter swimming pool, which is the more sensitive than anyone else has achieved.

This method is not only suitable for biological applications, but also can be used for detection where there is interaction between molecules in the liquid. Therefore, this method can also be applied to fuel cell monitoring and environment sensors.

* This result is based on joint research with electric manufacturers and other universities.

[1] T. Yanagitani and M. Kiuchi, “Control of in-plane and out-of-plane texture in shear modepiezoelectric ZnO films by ion-beam irradiation,” J. Appl. Phys., vol. 102, no. 4, 044115, (2007).

[2] T. Yanagitani, M. Kiuchi, M. Matsukawa, and Y. Watanabe, “Characteristics of pure-shear mode BAW resonators consisting of (11-20) textured ZnO films,” IEEE Trans. Ultrason., Ferroelectr., Freq. Contr., vol. 54, no. 8, pp.1680?1686, (2007).

2. Micro-viscosity sensor

In medical sites and bio-research sites, the determination of the viscosity of blood or other liquids is essential, especially technology that can detect microscale liquid samples of about one drop. Our lab is researching the determination of the viscosity by using the variation of the surface acoustic wave propagating at the interface of liquid and solid.

As shown in the figure below, the normal surface elastic wave (Rayleigh wave) will leak energy into the liquid, so it cannot be used for liquid material determination. Normally, the polarization of the piezoelectric films is perpendicular to the film surface (parallel to its thickness direction), and the piezoelectric films excite Rayleigh wave. In contrast, our lab successfully fabricated the world’s first piezoelectric film in which the polarization is parallel to the film plane, and the film clearly excites pure shear waves [3,4]. As a result, it is possible to fabricate the shear mode piezoelectric films on complex curved surfaces and slide glasses, and it is also expected for microscale liquid sensor applications.

* This result is based on joint research with electric manufacturers and other universities.

[3] A. Tanaka, T. Yanagitani, M. Matsukawa, Y. Watanabe, “Propagation characteristics of SH-SAW in (11-20) ZnO layer/silica glass substrate structures,” Proc. IEEE Ultrason. Symp., pp. 280?283, (2007).

[4] Y. Nakahigashi, T. Yanagitani, M. Matsukawa, Y. Watanabe “c-axis parallel oriented ZnO film SH-SAW sensor for electrical conductivity measurement in liquid,” Proc. IEEE Ultrason. Symp. pp. 810?813 (2011).

3. Ultra-high sensitivity ultrasonic probe

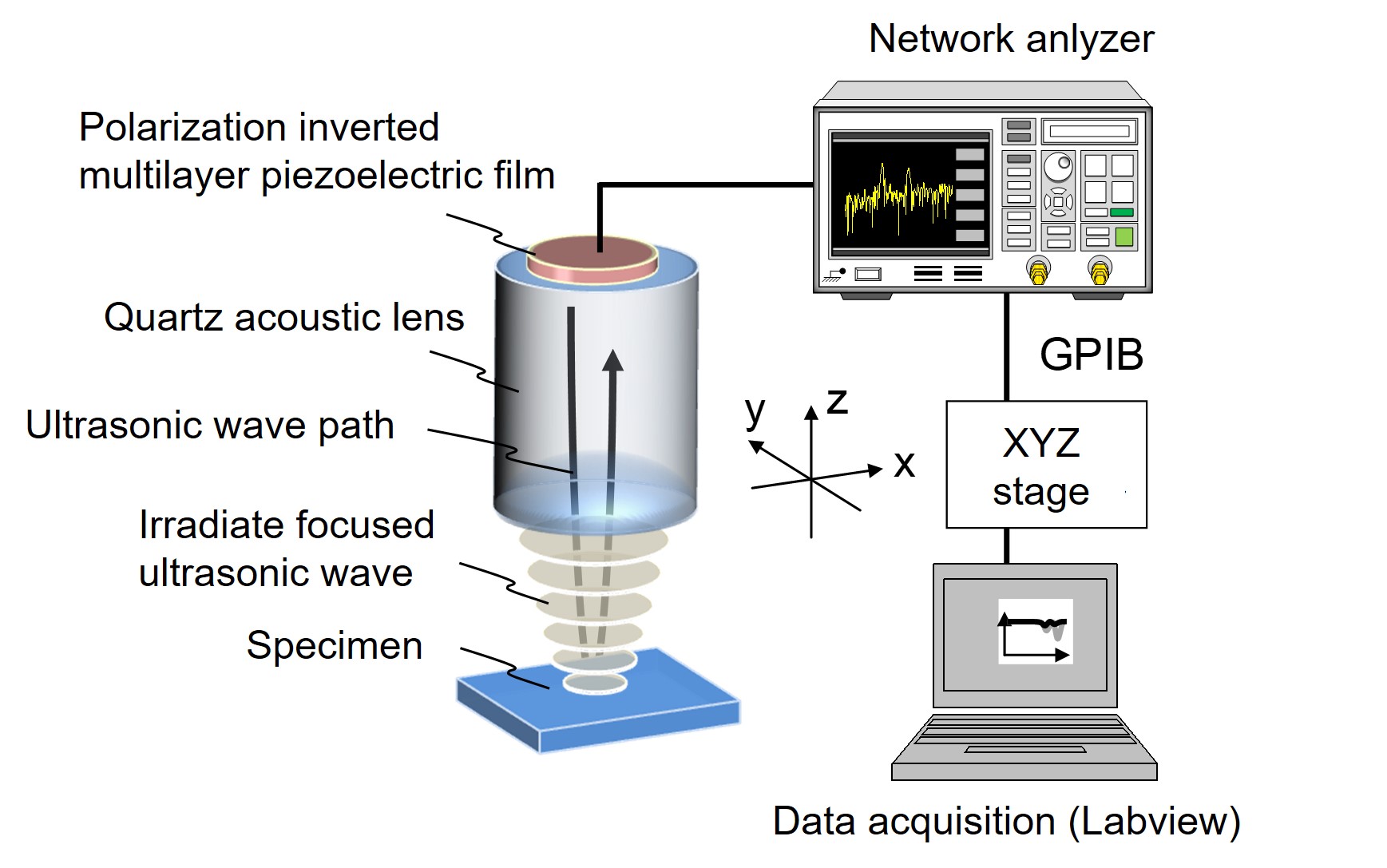

In recent years, the need for high-reliability detection devices, such as in-vehicle electronic components, has increased. Using ultrasonic microscopes to improve detection technology has become an important task. High-resolution detection devices are urgently needed due to the rapid progress of miniaturization and lamination. As shown in the figure below, most of the ultrasonic microscopes (imaging equipment) irradiate focused ultrasonic waves to components through a water coupler using the ultrasonic probe (transducer) composed of piezoelectric thin films and acoustic lens. The reflected wave is received by the probe again to visualize defects in the components. The resolution and sharpness of the image of the component defect are determined by the frequency and sensitivity of the probe [5].

Recently, our lab discovered the large piezoelectric coefficient of YbGaN thin films [6] and the polarity-inverted phenomenon in ScAlN thin films [7,8], which makes it possible to achieve a sensitivity that is more than five times that of the ZnO piezoelectric thin film used before. In addition, the practical use of these technologies in high-resolution medical imaging of biological tissues at treatment sites is just around the corner.

[5] 柳谷隆彦、鈴木雅視、高柳 真司「非破壊検査用の高分解能超音波プローブ」日本音響学会誌 vol. 71, no. 5, pp. 230?238 (2015)

[6] T. Yanagitani and M. Suzuki, “Enhanced piezoelectricity in YbGaN films near phase boundary,” Appl. Phys. Lett., 104, 082911 (2014).

[7] M. Suzuki, T. Yanagitani and H. Odagawa, ”Polarity-inverted ScAlN film growth by ion beam irradiation and application to overtone acoustic wave (000-1)/(0001) film resonators,” Appl. Phys. Lett., 104, 172905 (2014).

[8] T. Yanagitani and M. Suzuki, “Electromechanical coupling and gigahertz elastic properties of ScAlN films near phase boundary,” Appl. Phys. Lett., 105, 122907 (2014).

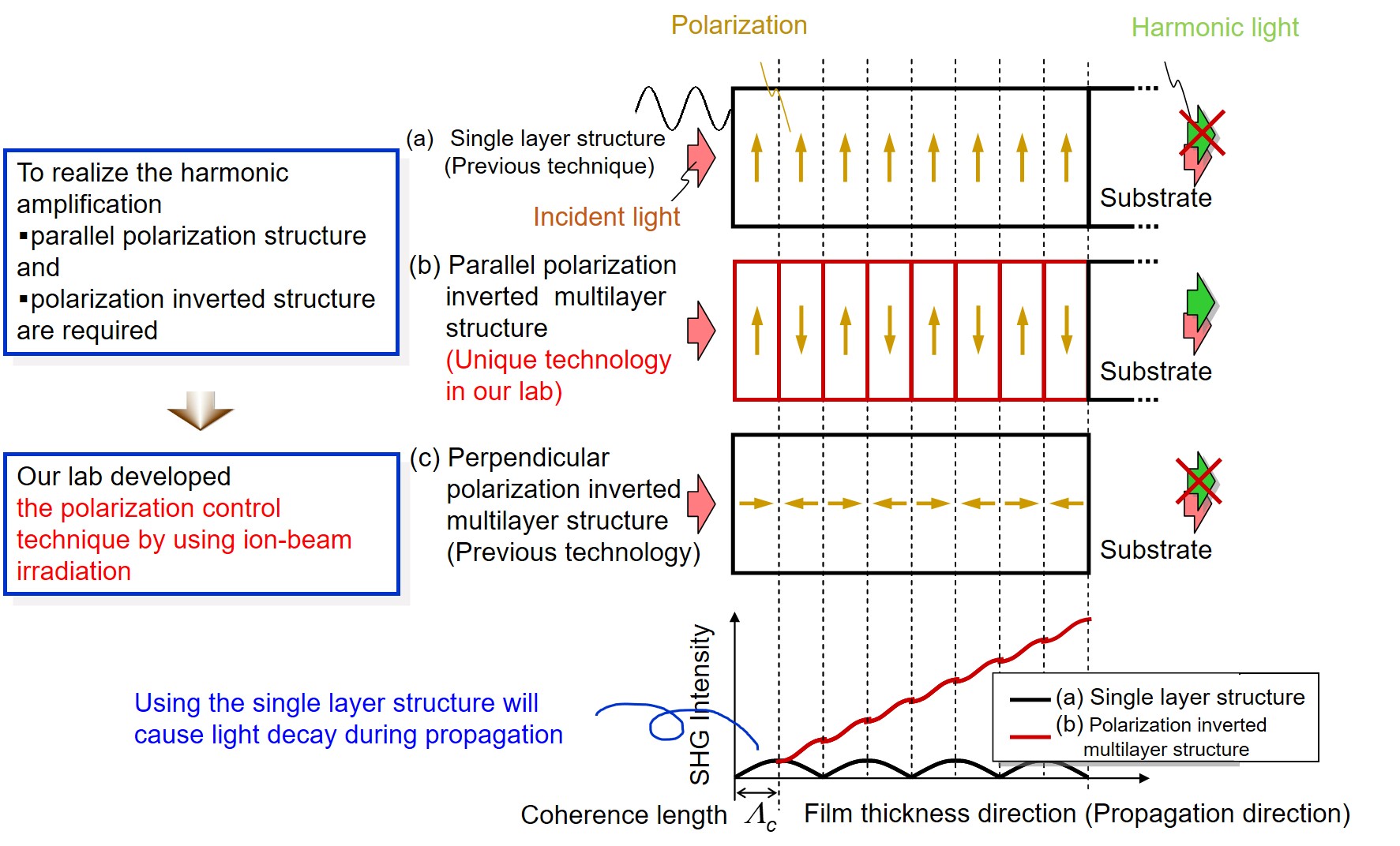

5. Frequency tunable filter for smartphone using polarization inverted ferroelectric epitaxial film multilayer structure

Coming Soon

[9] K. Katada, T. Yanagitani, M, Suzuki and K. Wasa, “Second harmonic mode polarization inverted resonator consisting of PbTiO3 thin film,” Proc. IEEE Freq. Contr. Symp., (2014).

6.A method for measuring wide band-gap semiconductors using interactions between carriers and acoustic waves

Coming Soon

[10] T. Yanagitani, H. Sano, and M. Matsukawa, “A method for measuring in-plane unidirectional electrical properties in a wide band-gap semiconductor using a Brillouin scattering method,” J. Appl. Phys., vol. 108, pp. 024910-1?024910-4, (2010).

7.Liquid conductivity sensor using the acoustoelectric effect

Coming Soon

8.Nonlinear optical devices using c-axis parallel polarization inverted multilayer film structure

Coming Soon

9.Chirality optical devices based on c-axis parallel polarization spiral multilayer film structure

Coming Soon

[11] M. Suzuki, T. Yanagitani, H. Odagawa, “Polarization inverted (0001) / (000-1) ScAlN film resonators operating in second overtone mode,” Proc. IEEE Ultrason. Symp. pp. 1922?1924, (2012).

10.ultraviolet light sensors using c-axis parallel polarization inverted multilayer film structure

Coming Soon

Reference: Our lab actively participates in various academic activities. Graduate students participate (do presentations) in international or domestic conferences 4 times a year on average.

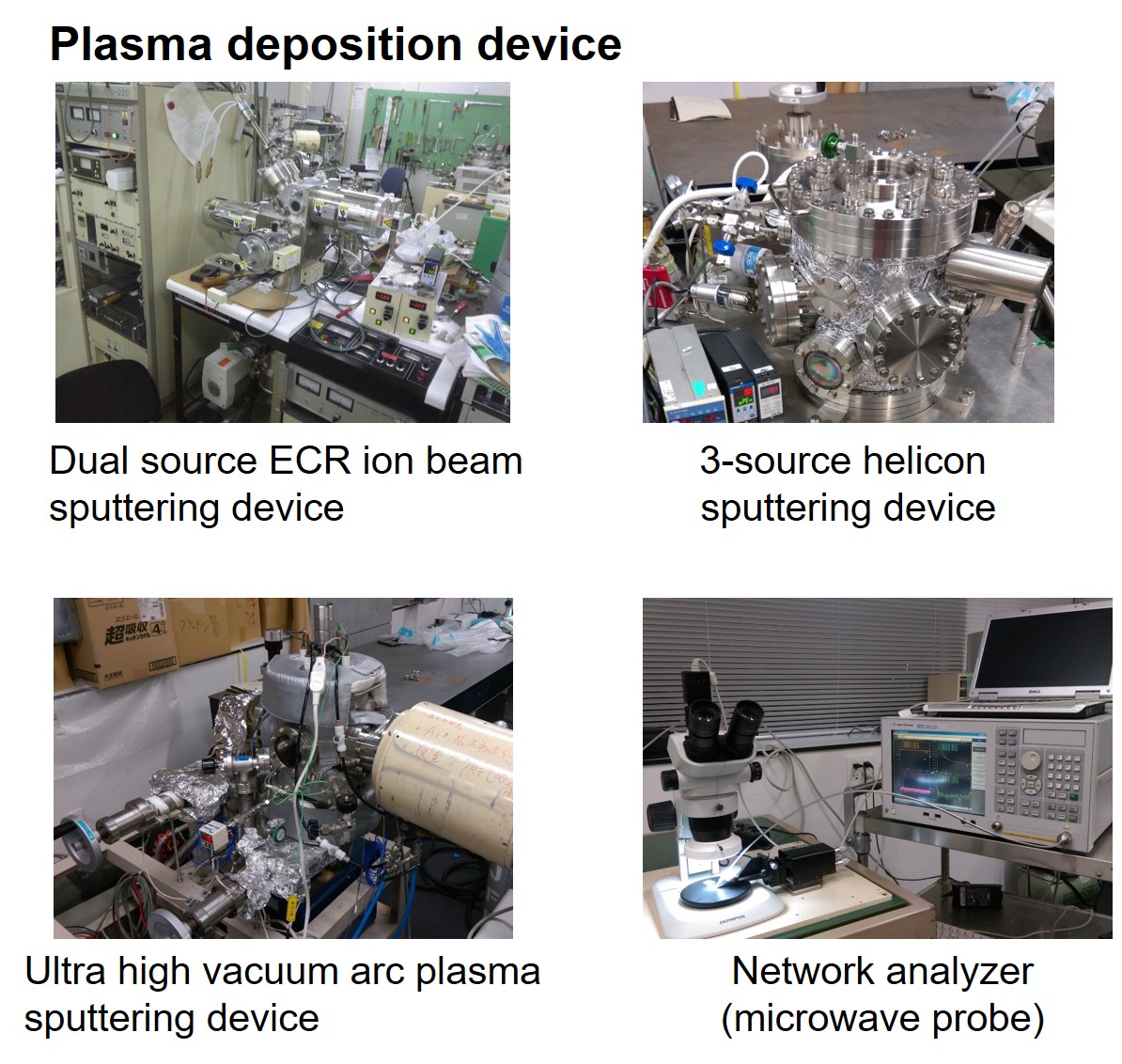

Homemade lab equipment